Picture a yacht in your head and you would probably imagine an idyllic bay or cove with turquoise waters in the height of summer. This is the aspiration that many have when they think of the yacht experience.

Whether island hopping in the Caribbean or seeking adventure in the colder reaches of the world’s oceans, the comfort onboard largely depends on the HVAC system. Enjoyment can erode pretty quickly without one and the space demands of a yacht are constantly trying to squeeze value out of every centimetre. This means that the HVAC system must occupy the smallest space possible while providing one of the yacht’s most important functions.

As one of the biggest energy consuming systems onboard, the HVAC system makes a significant contribution to the overall footprint of superyachts that, on average according to the Guardian, amounts to around 7,000 tonnes of CO2 per year. Between 50% and 60% of energy reservations on the total E-load regardless of situation – cruising, at anchor, crossing or in port, is taken up by the HVAC system.

HVAC solutions are offering owners cost and space-saving options that, as part of other solutions that take the load off the system such as window film application or heat recovery systems, are helping owners maximise usable space and therefore value of their prized asset.

Heinen & Hopman have worked alongside MB92 for many years and with service centres at both shipyards, work hand in hand with our team on projects. Before considering a system upgrade, reducing the workload of the system can help reduce energy consumption in the form of creating shade areas in the superstructure and incorporating alternative window materials or applying film. Furthermore, applying best practice in operations as well as maintenance can enhance performance as well as extend the lifecycle of the system.

Solutions

Smart design

Moving air around the yacht consumers energy so by dividing the yacht into different AC zones with air-handlers and vertical duct shafts central, the system’s efficiency is improved greatly. Furthermore, ducting carries weight so by utilising a smart design this can be reduced and also the need for fans that drive air to the more remote areas and valves required by the system.

Waste heat recovery

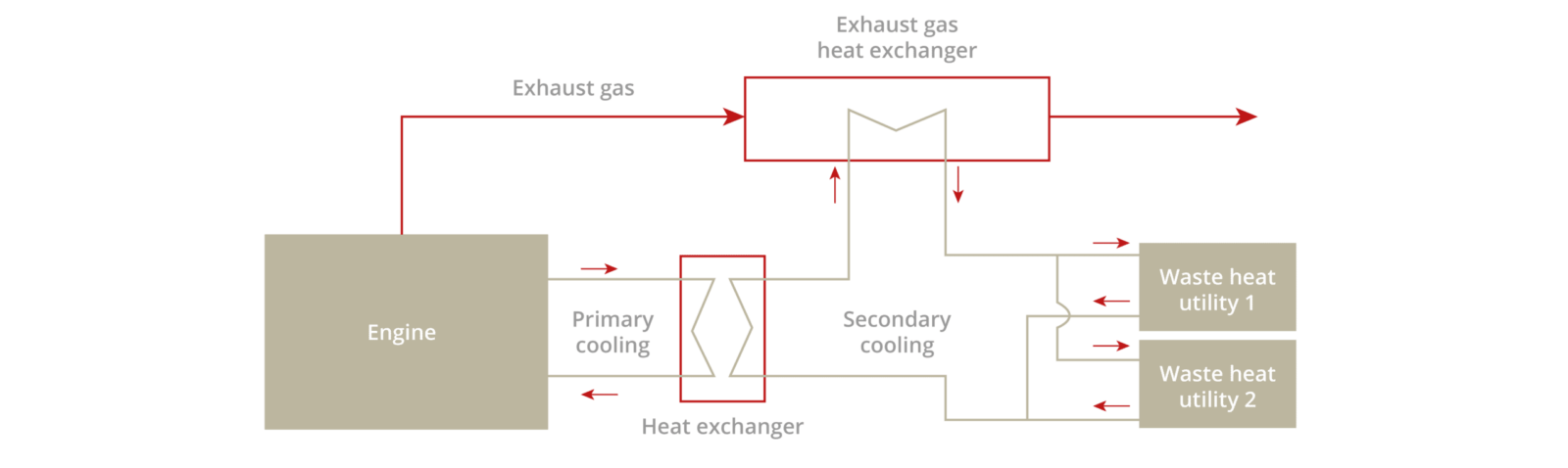

Most maritime diesel engines have an efficiency of 50% with remaining energy from fuel combustion released.

Waste heat recovery is an excellent measure to improve energy efficiency. The thermal energy is used to warm up the boilers for hot water plus the pre-heating and re-heating in air handling units.

Although extra heat exchangers and circulation pumps are needed, the complete heat demand is covered in most of the cases. Waste heat can also be used to power up an absorption cooling machine, providing chilled water.

Electric efficiency

An HVAC system is nothing more than a number of physical processes being driven by various main components. The use of these drive components is responsible for 75% to 95% of the HVAC’s total electricity consumption. Considerable savings can be enjoyed by making use of efficient solutions such as:

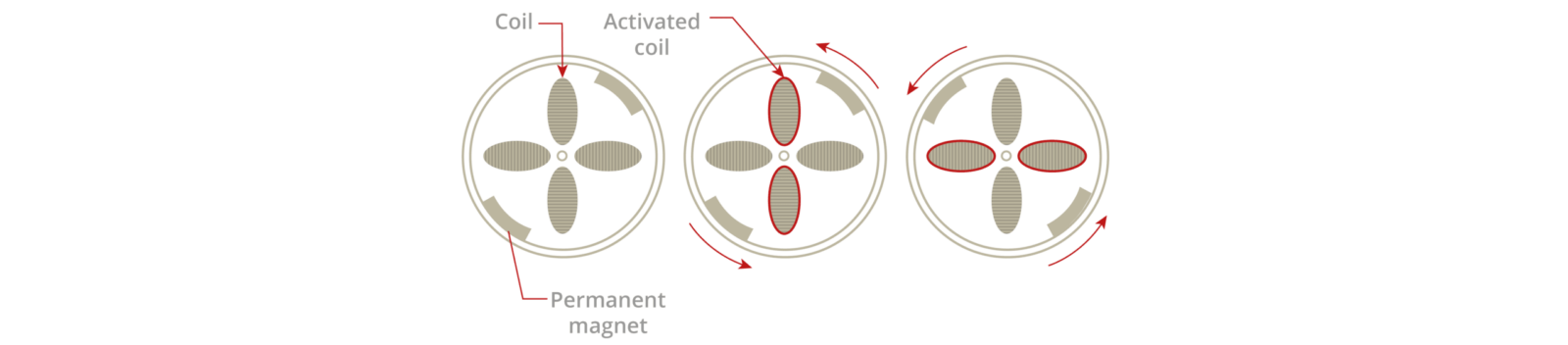

Brushless DC motors (Electronically Commutated Motors – ECM) – Require no maintenance, have immediate speed control, low on noise levels and, unlike brushed motors, produce no friction from contact with the shaft

Magnetic bearing compressors – Conventional compressor electromotors of the same size have efficiencies of around 92%. Magnetic compressors reach electric efficiencies up to 97% and deliver the same cooling capacity with a lower electrical power as it does not suffer from frictional resistance.

Return air recovery

Outside air is brought into the HVAC system for two purposes; support the provision of an indoor climatic environment and also to supply sufficient fresh air. Fresh air helps keep guests and crew healthy and comfortable. The system runs a treatment process before it is circulated and this carries an energy demand and not to re-use this energy is a waste. Energy recovery can be done in four main ways:

Recirculation – The air-handling unit provides the yacht with the necessary amount of treated air for a comfortable environment. Part is then recirculated along with a ratio of fresh air (typically 50/50 treated and fresh air)

Crossflow heat exchange – A crossflow heat exchanger within the air handling unit directs conditioned air crosswise along incoming air, facilitating heat transfer through conduction.

Twin-coil system- In a twin-coil system, there are two water-fed elements: the cooler and economiser. The system includes a circulation pump that transfers heat from the economiser to the cooler for energy recovery.

Heat recovery wheel – The heat recovery wheel achieves the highest efficiency rates at 70% by bringing incoming and outgoing air flows together in a rotating wheel. As the wheel turns, the warm and cold air exchange energy with the duct wall, resulting in efficient heat transfer between the air streams.

Start planning today

There are a number of solutions currently available to reduce emissions produced onboard and offer a variety of additional benefits from cost saving to comfort onboard. Refit for the future! offers clients a tailored refit plan built around the needs of each yacht to optimise sustainability and improve value.

To discover more on HVAC system options, other solutions in our Refit for the Future! service plan or to discuss your next refit period, please contact our team:

Hello, how can we help you today?

- I want to request a quote

- I want to get in touch with an MB92 Barcelona representative

- I want to get in touch with an MB92 La Ciotat representative

- I want to get in touch with an MB92 Red Sea representative

- I want to know more about MB92 Red Sea

- I want to apply for a job vacancy

- I want to get directions