At MB92, we pride ourselves on being able to offer our clients agile and effective solutions that result in practical benefits. In order to support us, we work alongside an incredible network of working partners who are pushing the envelope on innovation through projects, products and services that redefine what is possible.

In the first of a new series shining a light on innovation in our industry, we present the SKF RecondOil Box system.

Breaking convention

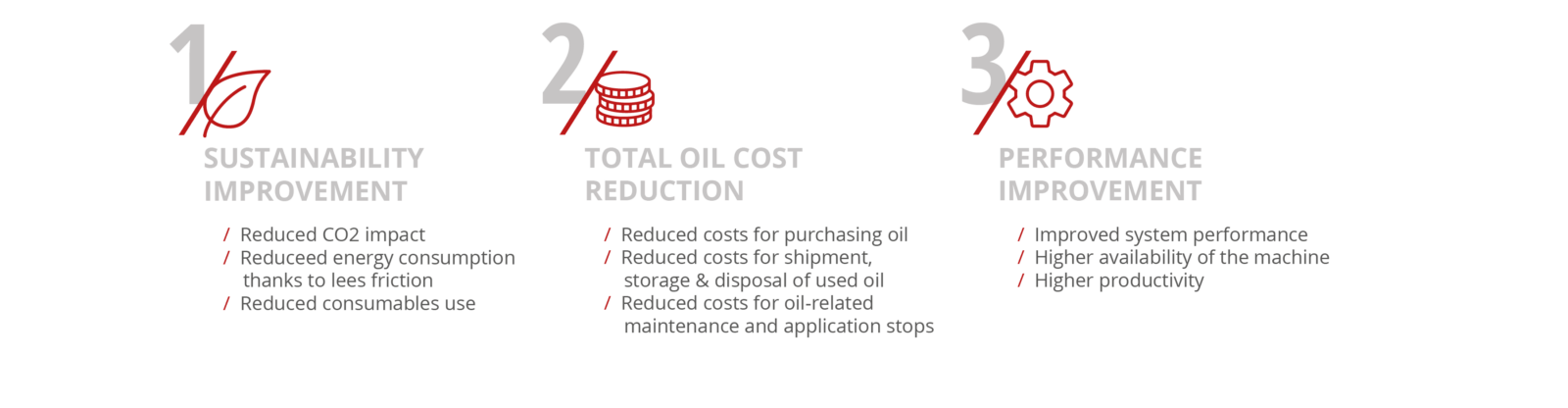

Machines require oil as everything in motion requires a lubricant. Traditional oil use is linear – it is added to the system, degrades over time, and is replaced. This degradation is a result of oxidation caused mainly by contamination from small particles (dirt, water, etc) that can lead to damage to equipment. The SKF RecondOil Box makes the shift to a circular use, turning the oil into a sustainable asset.

How does it work?

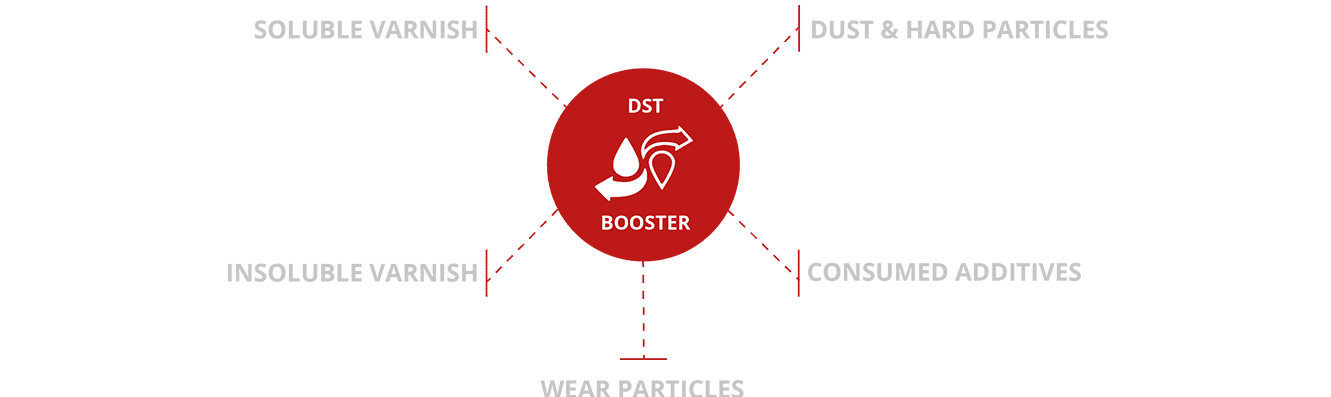

The RecondOil Box system is a plug and play unit that is easily integrated into onboard systems. It employs an SKF patented Double Separation Technology (DST) capable of attracting particles down to nano size, allowing the deep filtration system to remove all particles, water, soluble and insoluble varnish, and at the same time maintain the oil’s original properties.

As an additional benefit, oils bought off the shelf are not clean and already contain contaminants. This system can purify new oil to higher levels of cleanliness and thereby improve performance. Increased cleanliness can in turn result in less friction and lower oil temperatures.

Go circular for your next refit period

The unit is easy to install, with flexible arrangements available depending on the individual requirements of the yacht and includes regular monitoring and service support from the SKF team to ensure optimal performance.

Ready to say goodbye to costly and wasteful oil changes? Speak to our team to see how to get the most out of your next refit period.

Hello, how can we help you today?

- I want to request a quote

- I want to get in touch with an MB92 Barcelona representative

- I want to get in touch with an MB92 La Ciotat representative

- I want to get in touch with an MB92 Red Sea representative

- I want to know more about MB92 Red Sea

- I want to apply for a job vacancy

- I want to get directions