Providing the client with greater control and visibility

Life has changed dramatically for everyone over the past few weeks and with this change comes a variety of challenges. But change can also provide opportunities.

Many companies across the world consider that the way forward to adapting to the “new normal” is through innovation and addressing customer needs during this difficult time.

New technologies are emerging at a fast pace and there is huge potential for the superyacht industry to combine innovations from other sectors, such as the aviation industry that has provided inspiration for a number of solutions such as Noordung who are developing integrated control and communications systems for superyachts.

While forward thinking Owners are often making the most out of recent technological revolutions on their superyachts, the rest of the industry lags somewhat behind in their adoption in moving from traditional to smarter ways of working. Not only will this give individual companies a competitive edge but it also ultimately fuels sustainable growth.

The prevailing goal of technology in refit is to help professionals deliver higher quality service more efficiently, which will in turn improve the experience and reduce cost for the client.

For MB92, improving project efficiency and the overall refit experience for clients has always been at the forefront of our goals with a focus on streamlining processes and accelerating project turnaround times. Aside from the obvious advantages for owners whose yachts would be made more available for cruising, optimisation of the refit process would also benefit captains and yacht managers by providing them with even more control over their project.

The challenge

The Covid-19 crisis has presented a large variety of challenges, primarily how to orchestrate and deliver projects, which require the involvement of such a large and diverse number of people, while ensuring social distancing and the protection of everyone on site. On any given day, up to a thousand people can be operating within each shipyard from hundreds of local and international suppliers…

In Barcelona and La Ciotat, works on the 36 yachts in the shipyards were therefore initially suspended whilst we assessed our HSE procedures and equipment in order to ensure the safety of our clients, contractors and employees. While shipyard amenities were being maintained and the immediate needs of the 400+ crew members confined on board addressed, management began to analyse how to restart each project as swiftly as possible. It quickly emerged that two main hurdles would need to be overcome to do this; secure the appropriate personal protective equipment (via legitimate channels) and create new working procedures to control social distancing within the shipyards.

Challenge accepted!

MB92’s long-term ambition to provide clients with live tracking of works suddenly became a short-term necessity.

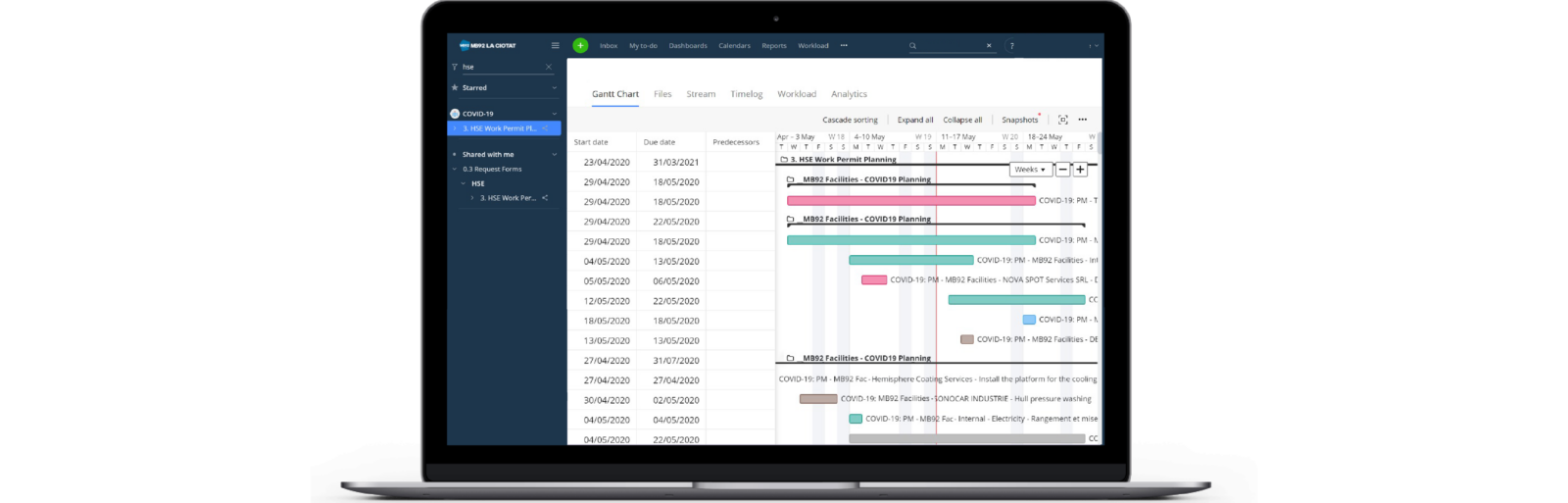

MB92 La Ciotat started to develop a new procedural system, via their project management software, linking with email and SMS verification processes which would not only minimise contact between workers, but would also provide project managers and clients with real-time knowledge of who is doing what, when and where.

How it works:

The system works via an approval process involving a series of automatic triggers and is initiated by the project manager when activating a task using an online form.

This new task request, complete with down to the hour planning – including lunch breaks – is sent to the HSE technical office who design the access and work zone plan for workers in accordance with other works being carried out. The drawings and planning then go through a multiple digital approval process from the HSE and the project manager and once approved the work request is automatically forwarded to the client for approval:

The client approves the access request, adding in any additional safety procedures that may be additionally required by the vessel such as temperature checks on entry. The contractor is then notified and accepts the timing of the works and confirms his team that will be completing the works.

The lead worker then automatically receives an SMS with instructions and access information and must sign in when arriving on board, triggering an automatic alert to the captain who receives a second alert when the worker leaves. Project managers and the HSE department are also automatically informed at each stage of this process, enabling them to keep abreast of all works in motion. Live dashboards show the number of people from each contractor at anytime on each vessel or any other location in the shipyard.

Implementing the new system

In less than four weeks, MB92 La Ciotat had procured the PPE needed to restart works on the site, and designed and implemented the new system for the live tracking of works.

Following several days of testing, this new tool is proving to be popular amongst clients and subcontractors, and will undergo additional modifications before being rolled out across the Group beyond the Covid-19 crisis.

Will Robinson, Captain of 60-metre Oceanco MY Helios provided some feedback on his experience with the new tool: “I’ve been coming to MB92 La Ciotat on a regular basis since 2007 because they are particularly good when it comes to the larger, more complex projects. They have a hands-on approach to solving problems and high standards of quality and control.

They’ve handled the current crisis well and the new system is great! I particularly like the SMS alert when contractors sign on board, besides its primary function it’s a great tool for tracking contractors. I hope they continue with this after the crisis as it’s has been really useful for providing real-time Information to the vessel.

The new system is great! I particularly like the SMS alert when contractors sign on board, besides its primary function it’s a great tool for tracking contractors.

Beyond Covid-19

MB92 is solution driven and we constantly strive to improve our services by always putting the client experience at the heart of everything we do. This approach has today enabled us to put technological innovation into the hands of our clients. Tomorrow, there will be more opportunities to transform their refit experience.

Follow #MB92 for the next chapter in our series of “Transforming the Refit Experience”

Hello, how can we help you today?

- I want to request a quote

- I want to get in touch with an MB92 Barcelona representative

- I want to get in touch with an MB92 La Ciotat representative

- I want to get in touch with an MB92 Red Sea representative

- I want to know more about MB92 Red Sea

- I want to apply for a job vacancy

- I want to get directions