We are increasingly conscious of the air quality around us and its impact on our well-being. We use purifiers in our homes and masks to counter the damaging effects of pollution in our cities. However, even on board a yacht at sea, we are not immune to air pollution. Motor yacht exhaust emissions can affect the air in and around the yacht, leading to potential health issues for owners, their families, and the working crew. It can also pose challenges in attracting charter guests or crew for the season.

IMO Tier III regulations came into force in 2016, affecting designated Emission Control Areas (ECAs), setting limits on NOx (nitrogen oxides) emissions which restrict navigation in these areas for non-compliant yachts. Able to be integrated into an upcoming refit period, the installation of a Selective Catalytic Reduction (SCR) system brings yachts into compliance.

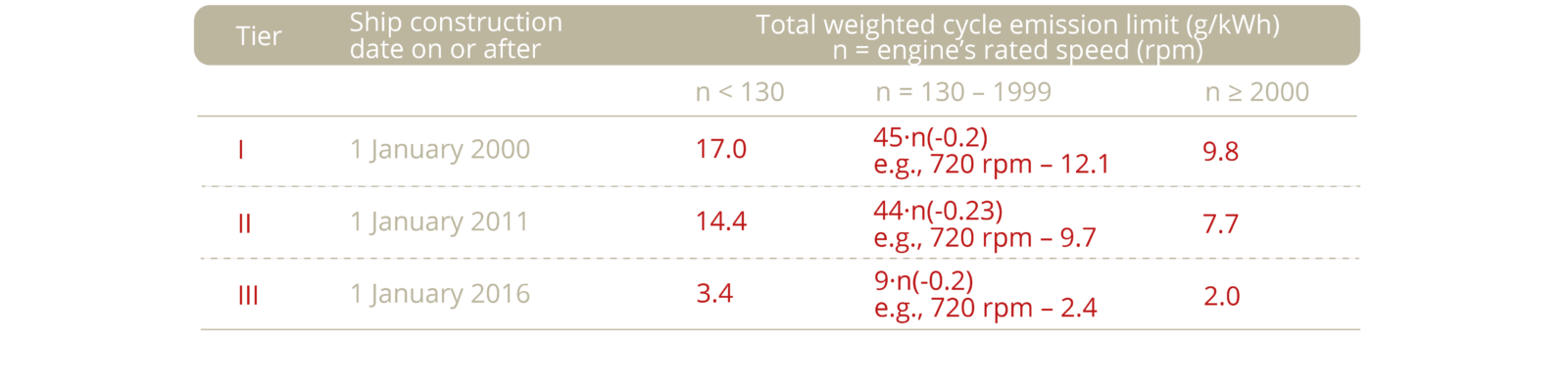

MARPOL Annex VI NOx emission limits

HUG Engineering, a trusted partner of MB92, specialises in advanced exhaust aftertreatment and has over 40 years of experience. In 2021, they launched a compact SCR system including technology for a reduced system footprint, allowing easy integration into engine rooms. This system not only ensures compliance but also offers the flexibility of being switchable between IMO Tier II and Tier III, saving urea outside ECA zones.

By combining several of our in-house experiences such as catalyst development, compact steelwork design including computational fluid dynamics (CFD) as well as certification expertise, we found the perfect balance between customisation and fast delivery times. To have a compact IMO Tier III solution based on a standard Tier II engine provides maximum flexibility for both new build and refit customers.

In addition to the SCR system, a Diesel Particulate Filter (DPF) can be added to further enhance the sailing experience by reducing soot emissions by more than 97%. Besides reducing toxic soot classified as carcinogenic by the WHO, it provides the benefit and pleasure of keeping the yacht and its surrounding water clean. Furthermore, noise reduction systems capable of reducing noise levels by 40-45dB contribute to overall comfort.

DPF and SCR systems can be used individually or in combination, respecting the space requirements of the engine room. With scope for complete customisation depending on the configuration of the space and pipe routing, the integrated solution is certified as Tier III compliant by DNV.

DPF (soot filters) should be applied to all superyachts. This system not only improves the quality of the air that surrounds the yacht, moreover the system avoids stains in the yacht paint & teak decks including any possibility of ash rain on the open decks.

Furthermore, an SCR system has no practical/visual direct impact on the daily use of the yacht, but it does allow emission reduction and guarantees that the yacht will be able to navigate worldwide for the following years, as regulations will become more restrictive in the upcoming ECAs.

How does SCR work?

The SCR system effectively reduces the concentration of nitrogen oxide in diesel engine exhaust gases to meet or exceed the emission limits set by IMO Tier III. It can even achieve NOx limits below IMO Tier III, such as the Ultra-Low Emission Vessel (ULEV) standards.

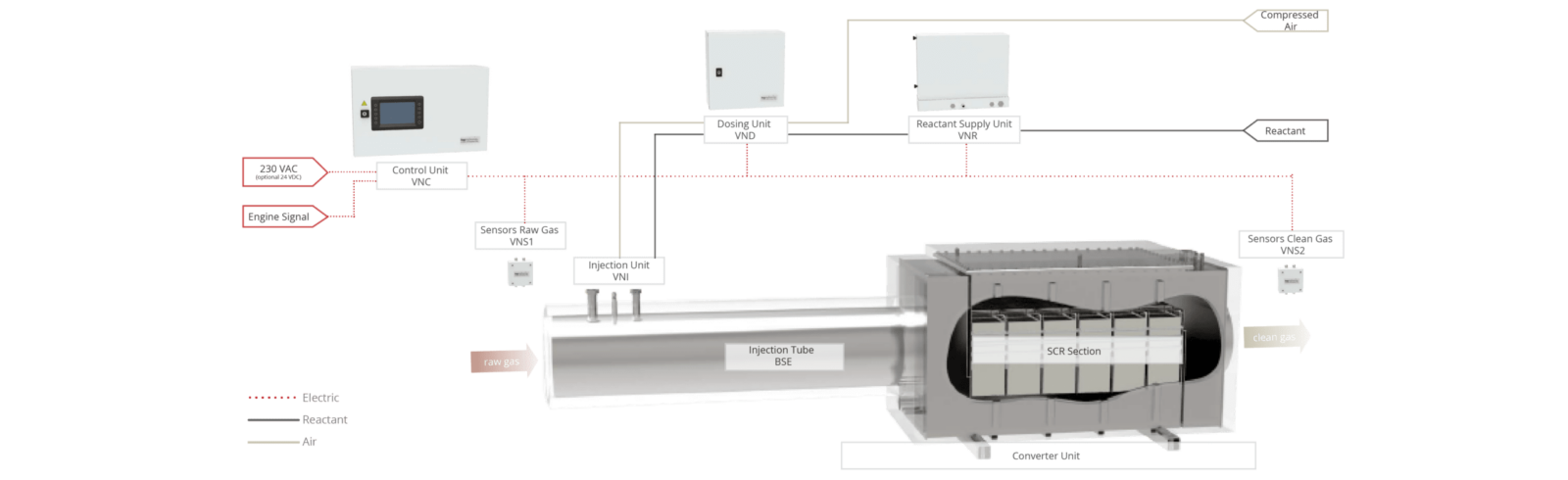

The system consists of the following main components:

- Injection tube

- Urea dosing system

- Converter unit

- Control system

A reducing agent (for example urea) is dosed into the exhaust gas. The exhaust gases and reducing agent react in the SCR catalyst, converting nitrogen oxide into nitrogen (N2) and water (H2O).

The length of the injection pipe is determined by the “minimum evaporation length” necessary for a correct chemical reaction to take place inside the converter. Therefore, space for evaporation, hydrolysis and mixing with the exhaust gases must be considered.

Here a compact SCR design provides benefits as the injection pipe is integrated into the reactor meaning the SCR can be installed on top of the engine, within the engine shape.

Start planning today

There are a number of solutions currently available to reduce emissions produced onboard and offer a variety of additional benefits from cost saving to comfort onboard. Refit for the future! offers clients a tailored refit plan built around the needs of each yacht to optimise sustainability and improve value.

To discover more on SCR system options, other solutions in our Refit for the Future! service plan or to discuss your next refit period, please contact our team:

Hello, how can we help you today?

- I want to request a quote

- I want to get in touch with an MB92 Barcelona representative

- I want to get in touch with an MB92 La Ciotat representative

- I want to get in touch with an MB92 Red Sea representative

- I want to know more about MB92 Red Sea

- I want to apply for a job vacancy

- I want to get directions